When municipal solid waste (MSW) is treated by incineration, the waste is centrally piled before combustion.Internal waste undergoes fermentation and decomposition, producing leachate that contains a high concentration of pollutants. If discharged untreated, it can cause severe pollution of water bodies and soil. Soil contaminated by leachate inhibits plant growth, and pollutants can accumulate in animals, posing serious risks to human health. Due to its complex composition and high treatment difficulty, leachate management is a critical aspect of municipal wastewater treatment.

I. Characteristics of Leachate

(1) High concentration of organic matter. Humic acids, large molecules synthesized from small organic acids and amino acids, are the primary persistent organic pollutants in leachate. Typically, 200–1500 mg/L of humic acids are non-biodegradable.

(2) High ammonia nitrogen concentration, generally below 3000 mg/L, often between 500–20,430 mg/L. It is not removed in anaerobic landfill conditions and is a major persistent inorganic pollutant in leachate.

(3) Leachate quality fluctuates significantly. COD, BOD, and biodegradability decrease over landfill time and gradually stabilize at low levels.

II. Leachate Treatment Technologies for Waste-to-Energy Plants

Back Spraying (Recirculation):

For leachate with high dry solid content, back spraying can be used to improve combustion efficiency and reduce harmful substance content. The need for re-combustion is determined by the leachate's calorific value. Using high-pressure systems, it is injected into the furnace. If the calorific value is below combustion standards, spraying stops, and leachate accumulates in a holding tank until concentration and calorific value meet requirements, ensuring treatment efficiency.

Before using this method, leachate production volume and calorific value must be measured. It is unsuitable for large volumes of low-calorific leachate, as it may cause flame extinction and poor treatment results. Back spraying is commonly used for food waste treatment with good results.

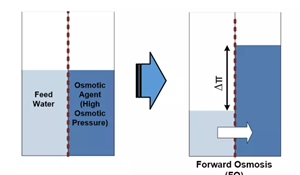

Reverse Osmosis:

After waste incineration, leachate concentration is much higher than from simple storage, and suspended solids content is greater. Using reverse osmosis (RO) membranes helps solve common pollution problems. When membranes accumulate significant suspended solids, they must be replaced promptly to maintain separation efficiency.

The RO method is primarily used to concentrate leachate and separate suspended pollutants. The resulting leachate is highly concentrated, making its treatment equally challenging. RO is often combined with other methods, with the concentrate being re-incinerated to minimize harmful substances.

Treating RO concentrate is a major challenge. Landfill leachate concentrate can be treated by recirculation into the landfill body, using buried waste to adsorb and degrade heavy metals and organics.However, for incineration plant leachate treated by RO, concentrate volume exceeds 50%. Lacking landfill recirculation options and being too voluminous for furnace spraying, solving the concentrate treatment issue is a prerequisite for using membrane technologies.

YHDE can undertake leachate treatment projects with various process combinations. We offer not only the standardized AIO-DTRO equipment applied nationwide but also the FOBC series equipment for higher leachate recovery efficiency, coupled with small-volume concentrate evaporation systems. This enables effective treatment of challenging leachate, achieving compliant discharge, near-zero liquid discharge, or emergency treatment to meet standards.

of Desulfurization Wastewater in Power Plants_.jpg)

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com