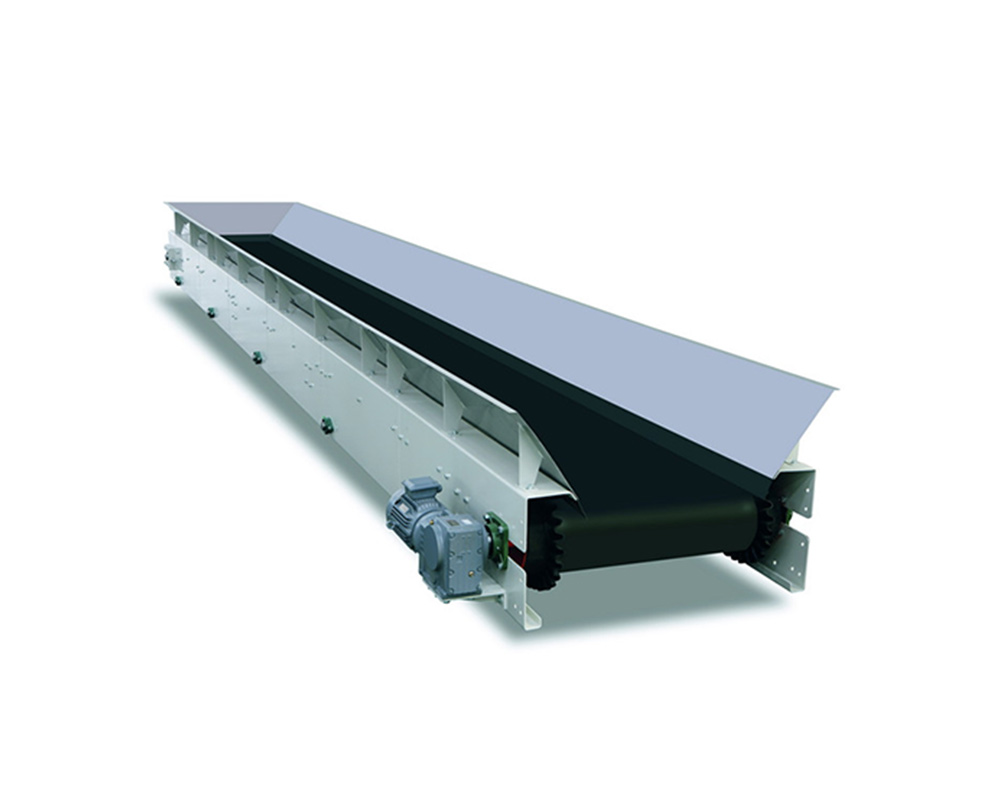

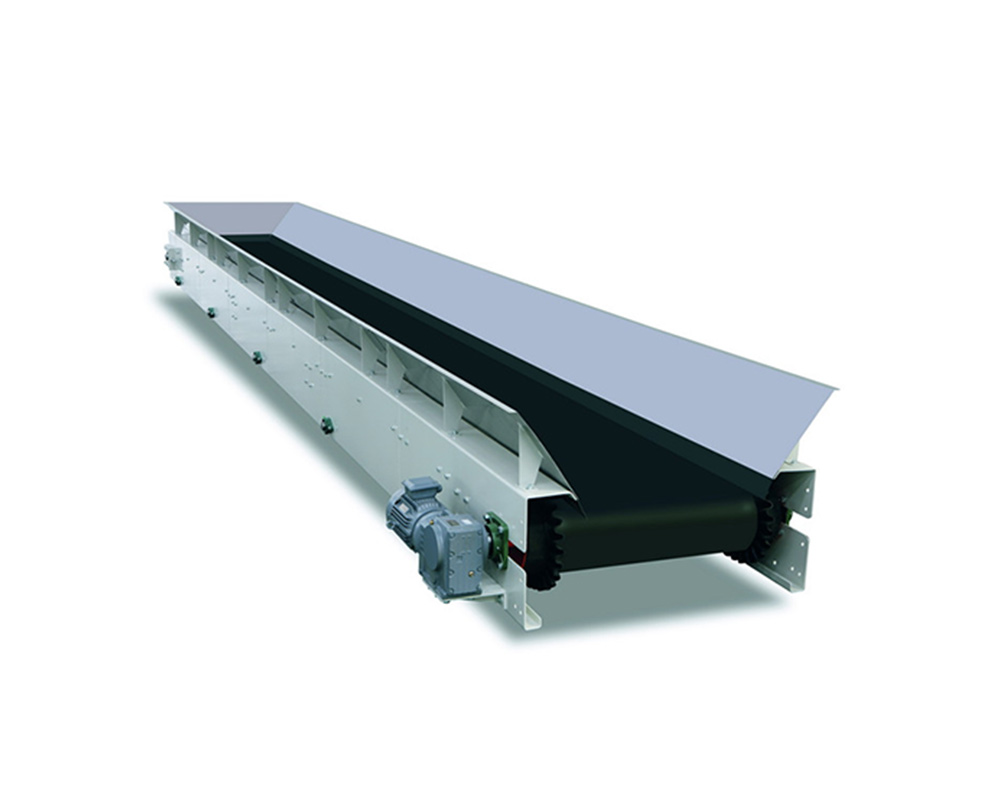

1. Simple and scientific structure, easy maintenance, high and stable conveying capacity;

2. Convenient operation, capable of fully automatic control;

3. Resistant to oil, acid, and alkali, able to transport various materials, with a long service life;

4. Traditional drum and permanent magnet drum options available.

The belt conveyor is characterized by oil, acid, and alkali resistance. The selection of belt width, canvas layers, and belt thickness is based on the conveying length, material, and conveying capacity to ensure longer equipment life. The belt conveyor can prevent material deviation during conveying, ensuring stable transportation.

The belt conveyor of features a simple structure, easy maintenance, stable conveying, large conveying capacity, standardized components, and high conveying efficiency. It is optimized and designed based on the working characteristics of the filter press. It can be arranged horizontally or inclined, and a single or multiple belt conveyors can be used in series according to the user's process requirements to form a complete material conveying system.

Due to the heavy weight of a single filter plate of a large filter press, it is inconvenient and requires a lot of work for workers to open the plates and unload the filter cakes. The speed of plate shifting can be controlled according to the proficiency of the operator. This system not only greatly improves the working efficiency of the filter press but also effectively reduces the labor intensity of workers, thereby reducing labor costs.

There are several methods for washing the filter cake of a filter press. Here are some of them:

Forward Crossflow Washing: In this method, the washing liquid is introduced into the filter press from the upper corner of the filter plates, while the washed filtrate is discharged from the lower corner. This causes the washing liquid to flow through the filter cake in a crossflow manner, effectively washing the cake and removing impurities.

Reverse Crossflow Washing: This method is similar to the forward crossflow washing, except that the washing liquid is introduced from the lower corner and the washed filtrate is discharged from the upper corner. The washing liquid flows through the filter cake in the opposite direction, providing thorough cleaning and removing any remaining impurities.

Mixed Crossflow Washing: As the name suggests, this method combines both forward and reverse crossflow washing techniques in alternating cycles. This ensures comprehensive and efficient cleaning of the filter cake.

The organization and optimization of these filter cake washing methods may vary depending on the specific conditions and process requirements.

YHDE Automatic Package Plate Shifting System uses a chain drive to open multiple filter plates in sections . This system opens multiple filter plates at once, greatly improving the filtration efficiency as well as discharge speed. As the driving chains on the transmission and opening device successively open the filter plates, the filter cake falls off by its own weight and is transported away by the conveyor below.

YHDE Automatic Package Plate Shifting System can open 3-30 filter plates at once, reducing the discharge time by 30%-70% and greatly improving production capacity and work efficiency while effectively reducing labor costs.

After the filtration process of the filter press is completed, the filter cake, other particles, and solids can be discharged into the matching mud storage hopper. This facilitates centralized one-time unloading and transportation, thus improving work efficiency. The size and various functions of the hopper can be customized according to the model of the filter press and customer requirements, meeting the usage scenarios of various industries and stages.

The efficient deep cone thickener has a small diameter, small footprint, easy installation, short construction period, large processing capacity, low coagulant consumption, high underflow concentration, and low overflow solid content. The stirring device has no power consumption, and the dosing system is equipped with an automatic dosing device, which can realize automatic operation and is easy to use.

The filter cloth tensioning, vibration and discharge device uses a zigzag linkage mechanism installed on both sides of the upper middle part of the filter plate. The filter cloth is connected to the zigzag linkage mechanism through connecting rods, springs, hooks, etc. During the unloading process, as the filter plate is pulled apart, the filter cloth vibrates in the zigzag mechanism due to the stretching of the spring, helping the cake to peel off the filter cloth.

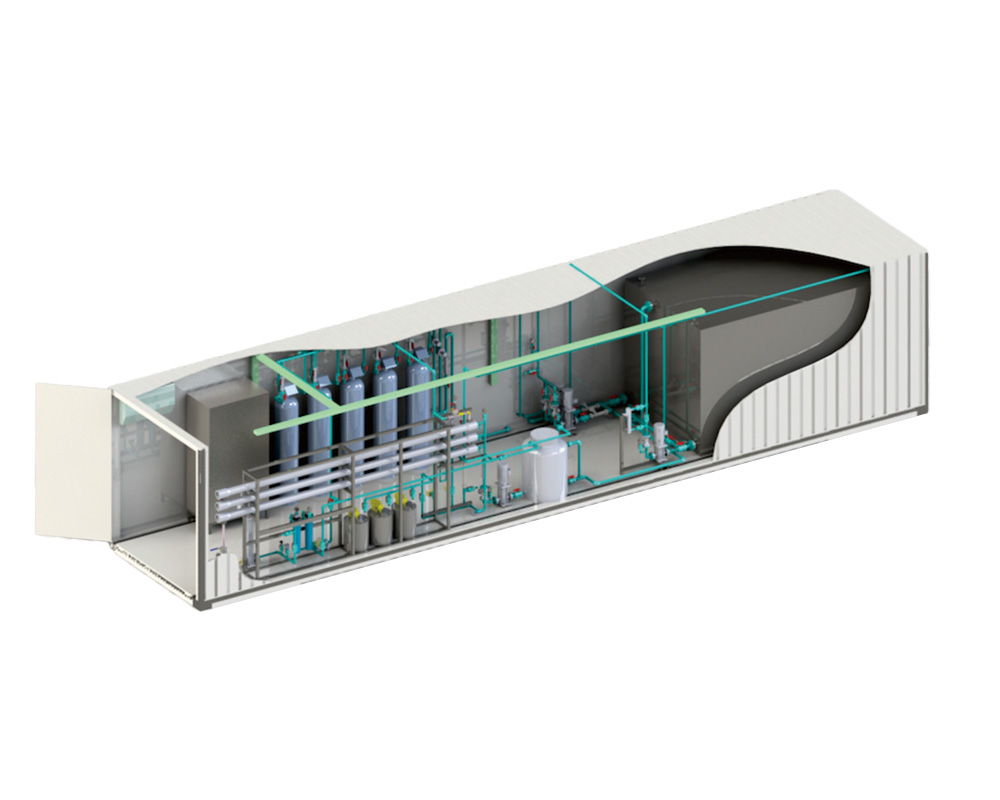

YHDE offers YHDE Reverse Air Blowing System / YHDE Filter Cake Drying and Dewatering System. These systems comprise an air compression system, compressed air storage system, and management system. Compressed air is stored in a tank after being compressed by an air compressor, and then delivered to the filter press through a pipeline.

YHDE Reverse Air Blowing System and YHDE Filter Cake Drying and Dewatering System can be selected separately or together, and share the same air compressor and storage tank to minimize costs.

The working principle of the screw conveyor is achieved by the rotating spiral blades pushing the material forward. The force that prevents the material from rotating with the screw conveyor blades is the weight of the material itself and the frictional resistance between the material and the casing of the screw conveyor.

YHDE screw conveyors can transport materials horizontally, inclined, or vertically, and can also be customized in different sizes and shapes according to requirements. They have the advantages of simple design, compact structure, small cross-sectional area, good sealing performance, easy operation, easy maintenance, and convenient closed transportation, occupying less space and with low maintenance costs, which can save costs for enterprises.

The belt conveyor of features a simple structure, easy maintenance, stable conveying, large conveying capacity, standardized components, and high conveying efficiency. It is optimized and designed based on the working characteristics of the filter press. It can be arranged horizontally or inclined, and a single or multiple belt conveyors can be used in series according to the user's process requirements to form a complete material conveying system.

The hydraulic power unit of the filter press is also called a hydraulic pump station or oil station, which is mainly composed of a hydraulic pump, a driving motor, an oil tank, a directional valve, a throttle valve, an overflow valve, and other hydraulic source devices or hydraulic devices including control valves. The hydraulic power pump station is a pump station that provides hydraulic power in the hydraulic system. It uses hydraulic oil as the medium, and the medium that meets the required flow rate and pressure is sent out by the pump (vane pump, gear pump, rotary pump, plunger pump, etc.) through the original power (electric motor or other power) to supply the hydraulic system.

Our company's filter cake crusher for filter press is designed to improve production efficiency and reduce operating costs. It adopts a simple and easy-to-maintain structural design, which can quickly crush the filter cake produced by the filter press.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com