Desulfurization wastewater is characterized by high salinity, complex composition, corrosiveness, and scaling tendency, making it difficult to reuse and becoming a key factor restricting the achievement of ZLD in coal-fired power plants. So, what ZLD technologies are available for desulfurization wastewater?

1.Evaporation Process: Through evaporation technology, the solution is concentrated to obtain a certain amount of solid solute and pure solvent. It is widely used in chemical, seawater desalination, and food industries. In practice, the heat of vaporization required is relatively large, making this process energy-intensive. Currently, the chemical industry primarily uses multi-effect evaporation technology to improve heating steam efficiency, enhance heat transfer conditions, and reduce unit energy consumption. The newly developed Mechanical Vapor Recompression (MVR) technology can effectively reduce steam consumption. This technology uses a mechanically driven compressor to adiabatically compress secondary steam, which is then sent to the heating evaporator. After compression, the temperature of the secondary steam increases, creating a temperature difference with the boiling liquid in the evaporator, allowing it to be used as a heating medium. By supplying sufficient compression work, the latent heat energy in the secondary steam can be fully utilized.

2.Comprehensive Utilization of Slag Waste Heat Technology: This technology involves introducing weakly acidic desulfurization wastewater to neutralize alkaline substances in the wet slag removal system and utilizing the waste heat from high-temperature slag to achieve evaporation and solidification of the wastewater, thus realizing ZLD. It also replenishes water lost in the wet slag system due to evaporation and slag removal. If the wastewater volume exceeds the necessary replenishment volume for the wet slag system, the wastewater must be reduced to maintain balance. If the wastewater volume is less than the necessary replenishment, it can be introduced directly. This method offers advantages of low investment and convenient operation. However, high concentrations of Cl⁻ etc., in the wastewater may cause equipment corrosion during concentration; pollutants like heavy metals and precipitated crystalline salts may affect slag disposal and comprehensive utilization. Power plant trials introducing desulfurization wastewater into wet slag systems showed no impact on normal operation, no significant corrosion or scaling, and very low heavy metal content in slag water. However, as wastewater quality and slag system operations vary between plants, potential issues like equipment corrosion, dewatering bin clogging, and pipeline scaling cannot be ignored and require more practice and theoretical research.

3.Flue Gas Duct Treatment Technology: This technology primarily involves treating wastewater within the flue gas duct using spray evaporation. It is widely used in food and chemical industries but has not been widely adopted in wastewater treatment. For desulfurization wastewater, using flue gas duct evaporation technology, spray technology is first used to atomize the wastewater and introduce it into the duct before the dust collector. The fine droplets, heated by high-temperature flue gas, rapidly evaporate, and the contained suspended solids and soluble solids transform into fine solid particles, which are carried into the dust collector and removed, achieving the ZLD goal.

4.Combining Desulfurization Wastewater and Fly Ash Technology: In thermal power plant operations, fly ash is often landfilled. Desulfurization wastewater has a moisturizing effect on fly ash, which can reduce dust during transportation. If fly ash is used for brick making or as a cement additive, the requirements for Cl⁻ content are usually low. However, using this technology, heavy metals from the wastewater may transfer to the fly ash, potentially affecting its utilization value.

5.Constructed Wetlands: Establishing constructed wetlands can reduce the concentrations of metals, nutrients, and suspended solids in wastewater through the action of plants, soil, and microorganisms. Constructed wetlands comprise various plant and bacterial components, and power plants can select appropriate components based on their specific pollutants. Constructed wetlands can effectively reduce concentrations of metals, nutrients, and suspended solids only if the chloride content is low.

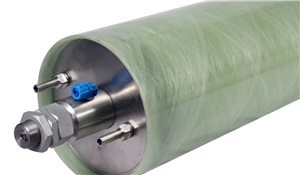

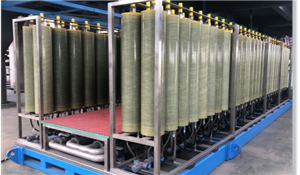

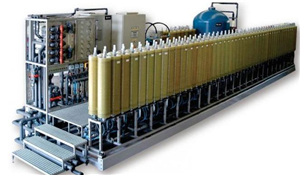

6.Steam Concentration Technology: This technology involves evaporating and concentrating wastewater to form distillate and concentrate. The concentrate is then further evaporated in a crystallizer or spray dryer to form distillate and solid waste, which can be recovered or landfilled. To prevent scaling in the evaporator, the wastewater must be pretreated to remove calcium and magnesium ions. Technologi.jpg)

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com