The pulp and paper industry, as an important basic raw material industry in the national economy, occupies a very important position. The paper industry is related to various aspects of a country's economy, culture, life, national defense, etc., and is a basic raw material for industry and daily life. Its uses span numerous fields in culture, education, science and technology, and the national economy, permeating all aspects of the national economy and people's livelihood. However, the papermaking process consumes many natural resources, and more seriously, also produces a lot of wastewater, so the development of the paper industry has been greatly hindered. To promote the healthy development of the paper industry, the goal of zero discharge of papermaking wastewater must be achieved.

Sources of Wastewater in the Pulp and Paper Industry

(1) Waste liquid generated from cooking wood pulp (or straw pulp), also called black liquor.

(2) Wastewater discharged from pulpers and refiners, called pulping wastewater.

(3) Paper machine wastewater, among which the portion that can be used directly is called white water.

Characteristics of Pulp and Paper Industry Wastewater

Papermaking wastewater has a complex composition and poor biodegradability, belonging to the category of industrial wastewater that is difficult to treat. The main pollutants it contains are the following:

(1) Suspended solids: including settleable suspended solids and non-settleable suspended solids, mainly fibers and fiber fines (i.e., broken fiber fragments and miscellaneous cells).

(2) Readily biodegradable organic matter: including low molecular weight hemicellulose, methanol, acetic acid, formic acid, sugars, etc.

(3) Hard-to-biodegrade organic matter: mainly originating from lignin and macromolecular carbohydrates contained in the fiber raw materials.

(4) Toxic substances: such as rosin acid and unsaturated fatty acids contained in black liquor.

(5) Acid and alkali toxins: alkaline pulping wastewater has a pH of 9-10, acid pulping wastewater has a pH of 1.2-2.0.

(6) Color: the residual lignin contained in pulping wastewater is highly colored.

Significance of Zero Discharge for Pulp and Paper Industry Wastewater

(1) The paper industry produces a lot of wastewater; the organic matter in its wastewater accounts for 25% of the total organic matter in domestic industrial wastewater in China, having a very serious impact on the natural ecological environment. Therefore, achieving zero discharge of paper industry wastewater is beneficial for improving China's natural ecological environment.

(2) Zero discharge of paper industry wastewater is conducive to increasing production and reducing emissions in the paper industry, improving the economic efficiency of the paper industry, forming good social and environmental benefits, and aligns with the sustainable development concept advocated by the state.

(3) Pulp and paper production generates a lot of wastewater. Papermaking wastewater has high BOD, and also contains many fibrous suspended solids. In addition, papermaking wastewater contains divalent sulfur and is colored; these substances cause very serious pollution and impact on the natural ecological environment. The wastewater also contains black liquor and white water, so it is essential to effectively remove the impurity content in the wastewater. Reducing the impurity content in wastewater not only meets environmental protection requirements but also improves socio-economic benefits.

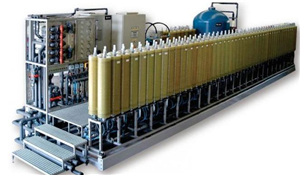

Application of Zero Liquid Discharge Process Technology for Papermaking Wastewater

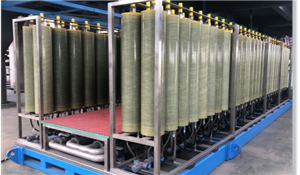

Membrane separation technology is an emerging efficient separation technology. Using membrane separation technology to treat papermaking wastewater can effectively remove dissolved inorganic salts and metal ions from papermaking white water, effectively reduce anionic trash substances, and can achieve the goal of zero discharge of papermaking wastewater.

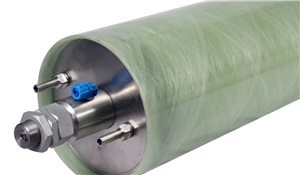

Reverse osmosis is often used in the treatment of papermaking wastewater. It is a liquid-phase membrane separation method using pressure difference as the driving force. This method for treating papermaking wastewater can effectively remove the large amount of salts contained in the wastewater, thereby improving the wastewater quality. The reverse osmosis process technology method has a good concentrating effect on papermaking wastewater. Through this method, the concentration of papermaking wastewater can be increased, effectively retaining the valuable components contained in the wastewater.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com