1. We Are Surrounded by Electroplating Technology Every Day

You may not have seen electroplating wastewater, but you definitely drive a car, take a bus or subway every day; in winter, you must use a stainless steel thermos cup; every day when you wash your face and brush your teeth, you must turn on the tap; and the pots, pans, bowls, and dishes you use for eating every day, the small accessories you like to wear, etc., are all made by further processing parts after electroplating.

However, while happily enjoying the convenience that electroplating technology brings to our lives, we have to face a problem: electroplating wastewater.

How is Electroplating Wastewater Generated?

Electroplating wastewater has five main sources: (1) Rinsing water for plated parts; (2) Waste electroplating solution; (3) Other wastewater: including water for washing workshop floors, water for rinsing electrodes, condensate from ventilation equipment, and various tank solutions and drainage water caused by tank leaks or improper operational management ("running, emitting, dripping, leaking"); (4) Equipment cooling water: except for a temperature rise, cooling water is not polluted during use; (5) Metal surface treatment: includes cleaning before surface treatment, electroplating, passive film protection, mechanical processing, and paint coating, mainly electroplating.

2. What Are the Hazards of Electroplating Wastewater?

Destruction of aquatic microorganisms: Acid and alkaline wastewater will destroy the living environment of aquatic microorganisms; the pH of the water source and the growth of aquatic plants and animals will also be affected.

Electroplating wastewater contains cyanide: Cyanide-containing wastewater is highly toxic; under acidic conditions, it generates highly toxic hydrocyanic acid. At low concentrations, it can cause short-term headaches and arrhythmia; at high concentrations, it can immediately cause human death. Even after cyanide poisoning is cured, neurological sequelae may occur.

Heavy metals in electroplating wastewater are highly harmful to the human body: Heavy metal ions are highly toxic substances that are carcinogenic, teratogenic, or mutagenic. Chromium damages human skin, the respiratory system, and internal organs; excessive zinc causes general fatigue, dizziness, and acute gastroenteritis; ingestion of zinc chloride causes peritonitis, shock, and death; copper affects the growth of human hematopoietic cells and the activity of some enzymes and endocrine function; cadmium causes prostate cancer and itai-itai disease (bone pain), and also leads to lung cancer; long-term intake of lead causes chronic poisoning due to its accumulation in the human body.

3. How to Treat Electroplating Wastewater and Achieve "Zero Discharge"?

Firstly, traditional electroplating wastewater treatment processes have excessively high costs, and heavy metals are discharged into water bodies without recovery, which can easily harm organisms.

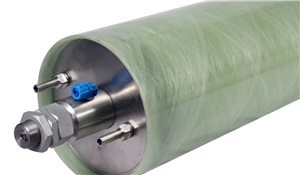

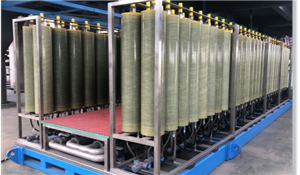

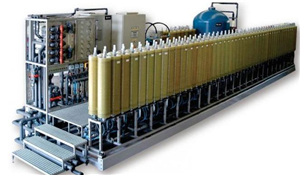

Secondly, membrane separation technology enables the recycling of water and heavy metals. Electroplating wastewater treated with membrane separation technology can achieve "zero discharge" or "micro discharge" of heavy metals, greatly reducing production costs. Using membrane separation technology, heavy metals and water resources can be recovered from electroplating wastewater, reducing or eliminating their environmental pollution, and achieving clean production in electroplating. For high-value-added electroplating wastewater containing gold, silver, nickel, copper, etc., using membrane separation technology can achieve a closed loop and generate good economic benefits. For comprehensive electroplating wastewater, after simple physico-chemical treatment, using membrane separation technology can reuse most of the water, with a recovery rate of 60% to 75% or higher, reducing the total sewage discharge and cutting pollutants discharged into water bodies. Therefore, using membrane separation to treat electroplating wastewater has received unanimous praise in the industry.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com