1. Adsorption Method:

The use of materials with a polymeric structure, such as activated carbon and zeolite, to adsorb organic matter in landfill leachate. After removing non-biodegradable organic compounds, the leachate becomes much easier to treat. The most commonly used adsorption method currently is activated carbon adsorption. A two-stage SBR system with reflux is typically employed; such a treatment method can adsorb up to 91% of organic matter and over 85% of metal ions from landfill leachate.

Disadvantages: The adsorption efficiency of various adsorbents differs significantly for different types of leachate. Furthermore, due to the limited adsorption capacity of adsorbents, using the adsorption method alone cannot achieve ideal results. It is currently mostly used as a pre-treatment method for leachate.

2. Precipitation Method:

The use of chemical means to precipitate and filter out substances in landfill leachate for purification purposes. Among chemical precipitation methods, coagulation is the most common and effective method. It involves preparing coagulants from various chemical reagents, such as ferric chloride and aluminum sulfate, and using coagulation-sedimentation technology to continuously separate heavy metal ions and other organic particles from landfill leachate through chemical means.

Disadvantages: Low removal rate of organic matter (around 50%). Although this method is simple and fast, it has high costs, and its facilities are not perfect.

3. Biological Treatment:

A wastewater treatment method where wastewater or solid waste is mixed and contacted with microorganisms, which use biochemical reactions within their bodies to decompose organic matter and certain inorganic toxins (such as cyanides, sulfides, etc.) in the wastewater, converting unstable organic matter and inorganic toxins into non-toxic substances.

Disadvantages: Poor degradation of synthetic organic compounds, significant influence by environmental factors, relatively low overall degradation efficiency, and excessively high fixed investment costs, which greatly limit its widespread promotion.

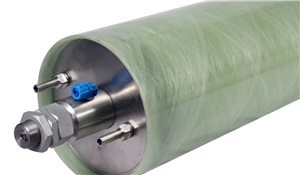

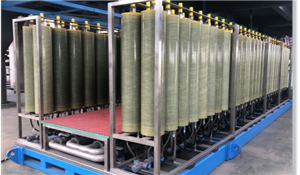

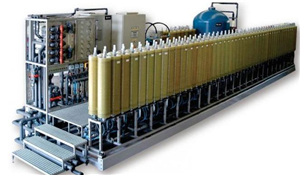

4. Membrane Treatment:

A water treatment method that uses membrane technology to separate particles; it is currently a more common and widely used method for treating landfill leachate. The principle of membrane treatment for landfill leachate is very simple—using a membrane to filter out solutes for purification. Among membrane technologies, reverse osmosis is the most effective technology, capable of effectively retaining various dissolved substances in wastewater, including organic and inorganic matter. Using low-pressure polyamide membranes and controlling the operating pressure allows complete control of the permeate flow and concentration. Through membrane treatment, 90% of organic matter can be effectively removed from landfill leachate, with a COD removal rate as high as 97%. Furthermore, membrane technology can also increase water recovery, significantly reduce the concentration and volume of landfill leachate, and achieve the goal of rapid treatment. Membrane treatment for landfill leachate has already been widely implemented in municipal solid waste landfills.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com