In textile dyeing wastewater, there are many types of materials with high COD values, among which synthetic thickeners and hard detergents have the most significant impact. Detergents have a chain structure, and their molecular volume is much larger than that of water molecules. Generally, depending on the molecular size, membrane methods can be used for separation. However, detergents are an exception due to their surface activity, which causes surface swelling; thus, ultrafiltration is not suitable for separating detergents. A more feasible method is to utilize their surface activity: by blowing air to create bubbles, detergents gather on the surface of the foam, and through further fractional distillation, detergents can be further concentrated and separated.

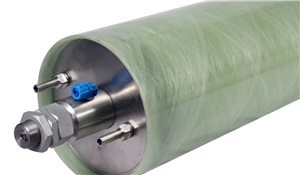

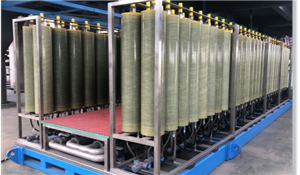

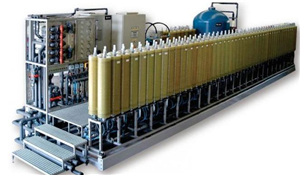

Another component that significantly affects COD values is synthetic thickeners. These generally include thickeners for warp sizing in the weaving process, printing pastes, finishing pastes, and thickeners contained in coatings. Among them, PVA (polyvinyl alcohol) for warp sizing is a component with relatively uniform composition and large quantity. Practical methods for separating and recovering PVA include chemical coagulation, ultrafiltration, and evaporation. The chemical coagulation method uses a concentrated sodium sulfate solution as a dehydrating agent and adds borax as a cross-linking agent to accelerate coagulation. At this time, PVA coagulates into a gel-like substance and separates from water. However, the chemical coagulation method has many disadvantages: about 10% of PVA remains in the wastewater; inorganic salts (sodium sulfate and borates) are added to the discharged water; when reusing coagulated PVA, the pH must be adjusted to 5 for dissolution, and it cannot be stored for long, otherwise it will undergo acid hydrolysis and lose viscosity; in the continuous coagulation process, the initially coagulated PVA adheres to the vessel walls and stirrer, affecting the continuous operation process. The ultrafiltration method for separating and recovering PVA is widely used abroad.

Before ultrafiltration, the PVA desizing solution must first undergo fine rope filtration to remove impurities introduced during the singeing process, avoiding clogging in the ultrafiltration device. During ultrafiltration, the PVA solution must be heated to reduce the viscosity of the solution; otherwise, the water permeation rate through the membrane will be too low. The evaporation method involves evaporating the entire slurry to a concentrated state, which does not cause material loss and does not require adding other chemical reagents. The disadvantage is high steam consumption. To reduce steam consumption, Japan uses a two-effect vacuum evaporation method, but single-effect high-temperature evaporation at excess pressure yields better results than two-effect vacuum evaporation. Compared to vacuum evaporation, excess pressure evaporation does not require vacuuming, and the secondary steam generated by evaporation does not need condensation but is output as low-pressure steam for multiple uses. For the evaporation separation method, the viscosity of the solution greatly affects the evaporation efficiency. When the viscosity is high, the circulation speed of the solution is slow, the heat transfer rate is low, and water evaporation is slow. Therefore, for evaporating and separating PVA, high-temperature evaporation at excess pressure is far superior to low-temperature vacuum evaporation. At the same time, high-temperature evaporation at excess pressure requires minimal steam consumption. The high-temperature excess pressure evaporation method can overcome the disadvantage of high steam consumption in the evaporation method. For other synthetic thickeners, the possibility of recovery and reuse is not great, but it is best to separate them as well, preventing direct discharge into wastewater to reduce the wastewater load.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com