DTRO (Disc-Tube Reverse Osmosis membrane system) process principle Leachate advanced treatment process — DTRO (Disc-Tube Reverse Osmosis membrane system).

DTRO (Disc-Tube Reverse Osmosis membrane system) technology is a membrane separation technology driven by pressure. Its basic principle uses pressure difference as the driving force, applying pressure exceeding the solution's osmotic pressure to the semi-permeable membrane, forcing water from the concentrated solution to permeate to the dilute solution side of the membrane, while the concentrated solution is continuously concentrated and remains on the other side of the membrane, achieving the purpose of separating solute and water. In the reverse osmosis asymmetric membrane, the main role in separation is played by the densely arranged surface thin layer of high-molecular polymer. Through the sieving effect of substances and the solvent-solute-membrane surface polymer filtration effect, it can remove almost all impurities in water including various inorganic salts, molecules, organic colloids, bacteria, viruses, pyrogens, etc.

The pressure applied on the concentrate side is related to the osmotic pressure of the solution. Theoretically, as long as the pressure applied on both sides of the reverse osmosis membrane exceeds the osmotic pressure, reverse osmosis phenomenon can occur. However, in the actual operation of the equipment, due to the influence of factors such as concentration polarization, the applied pressure is often several times the osmotic pressure.

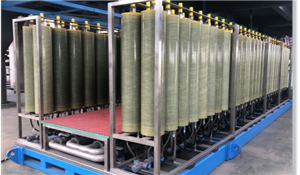

DTRO (Disc-Tube Reverse Osmosis membrane system) advantages: Proprietary fluid dynamics and unrestricted open channel structure and thoroughly turbulent feed water flow system mean suspended solids in the feed (raw water) are not prone to clogging the internal parts of the membrane module. *Importantly, the low-frequency and efficient built-in automatic cleaning system achieves an extended membrane module lifespan of up to 5 years.

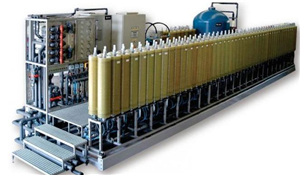

Based on the analysis of the advantages and application scope of various membrane technologies, to successfully retain pollutants in leachate (especially total nitrogen), it must be DTRO (Disc-Tube Reverse Osmosis membrane system).

In the DTRO (Disc-Tube Reverse Osmosis membrane system) treatment unit, generally most organic matter and nitrogenous pollutants have been removed from the ultrafiltration system effluent, but it still falls far short of the discharge standards, so advanced treatment using membrane separation technology is still required.

DTRO is currently the most technologically advanced and most reliable water treatment equipment in the water treatment industry. The system uses disc-tube reverse osmosis membranes. The principle is that under pressure, water molecules pass through the reverse osmosis membrane, while impurities in the water are retained by the reverse osmosis membrane and carried away by the concentrate. Using reverse osmosis technology can effectively remove impurities such as dissolved salts with large molecules, colloids, bacteria, viruses, bacterial endotoxins, and most organic matter. The system's divalent salt rejection rate is generally over 99%. Furthermore, the system has advantages such as simple operation, stable operation, and low energy consumption.

The disc-tube reverse osmosis membranes used belong to the category of dense membranes. Their biggest advantage is high filtration grade and good effluent quality.

Reverse osmosis separation can reach the ionic level. Its operating mechanism is still not very clear to date. It is generally believed that the mechanism is the selective adsorption-capillary flow mechanism: Due to the hydrophilicity of the membrane surface, it preferentially adsorbs water molecules and repels salt molecules, thus forming a pure water layer two water molecules thick on the membrane skin layer. When pressure is applied, molecules from the pure water layer continuously pass through the capillaries of the reverse osmosis membrane. Controlling the pore size of the skin layer is very important, affecting the desalination effect and water permeability. Generally, when the pore size is twice the thickness of the pure water layer, it is called the critical pore size of the membrane, achieving ideal desalination and water permeability effects.

Therefore, the rejection rate of reverse osmosis membranes for organic pollutants, divalent salts, etc. reaches over 99%, but the required osmotic pressure is large, and the product rate is low. Generally, the reverse osmosis permeate (clean liquid) product rate is around 80%.

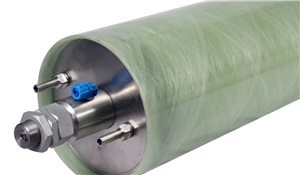

Disc-tube reverse osmosis membranes are a new type of membrane module structure specifically developed for leachate treatment. They use a spiral-wound membrane structure, the membrane sheets use industrial anti-fouling RO membranes, and the feed spacer channels use a parallel grid structure different from ordinary spiral-wound membranes, enabling them to operate stably for long periods in applications where ordinary spiral-wound membranes cannot be used.

Disc-tube reverse osmosis membranes have the following three distinct characteristics

1.Wide channel: The channel between membrane sheets (guide disc) is 6mm, while spiral-wound membrane modules are only 0.2mm.

2.Short flow path: The flow path of liquid on the membrane surface is only 7cm, while spiral-wound membrane modules are 100cm.

3.Turbulent flow: Due to the high pressure, leachate hitting the bumps on the guide disc forms high-speed turbulence. Under this turbulent scouring, pollutants are not prone to settling on the membrane surface. In spiral-wound membrane modules, the mesh spacer traps pollutants, forming stagnant areas leading to membrane sheet fouling.

Disc-tube reverse osmosis can tolerate relatively high suspended solids SS/SDI/high recovery rate.Put simply, even if muddy water enters, it is not prone to clogging!

Other characteristics of disc-tube reverse osmosis membranes:

Simple pretreatment, low feed water quality requirements, high recovery rate, high salt rejection;

High operating pressure, strong drainage, wide fluid channels, high tolerance to maintenance and cleaning, simple and convenient maintenance and replacement;

Low operating costs, small footprint, wide application range.

This reverse osmosis membrane is particularly suitable for landfill leachate treatment, petrochemicals, seawater desalination, acid and alkali recovery, emergency mobile water treatment, etc. However, the initial investment cost is relatively high.

Disc-tube reverse osmosis membrane modules have the characteristics of high-pressure resistance and anti-fouling. The distance between guide discs is about 3mm, and the upper and lower surfaces of the guide discs have irregular bumps. This unique structure reduces membrane clogging and concentration polarization on the membrane surface, improves the membrane operating environment, and extends the membrane sheet service life. Whereas traditional spiral-wound membrane modules are made by winding membrane sheets around a central permeate tube, with spacers forming the gap. Traditional spacers have a diamond structure, high resistance, which prevents spiral-wound membranes from operating stably for long periods.

Although spiral reverse osmosis membranes have simple pretreatment, low operating pressure, relatively low upfront investment costs, they have high feed water quality requirements, low recovery rate, low salt rejection, weak drainage, narrow fluid channels, low tolerance to maintenance and cleaning, require replacing the entire membrane module during maintenance, high operating costs, large footprint. Suitable for standard media, standard membrane modules, large-scale plants.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com