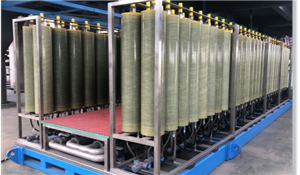

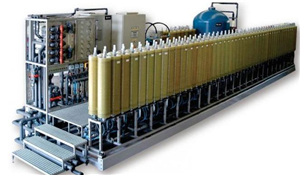

Nowadays, how to effectively treat and reuse wastewater has become one of the key issues in industrial water treatment. Disc-Tube Reverse Osmosis (DTRO) membranes have gained wide user recognition due to their stability, simple operation, and low cost.

The new Disc-Tube membrane modules (XDTRO) use membrane raw material from the American company Dow and are produced automatically utilizing German technology and equipment, ensuring excellent quality. They are now widely used in fields such as molecular separation, desalination, and liquid purification. Disc-Tube membrane modules have broad application prospects in high-concentration industrial wastewater treatment, high-salinity water concentration, landfill leachate treatment, brackish water desalination and purification, and domestic wastewater reuse.

Our patented fluid dynamics design, unique open channel design, and sufficient turbulence greatly improve the anti-fouling and anti-scaling capabilities of the Disc-Tube membrane modules. There are virtually no limits on feedwater SS; a Silt Density Index (SDI) of less than 40 is acceptable; salinity can be greater than 5%; feedwater COD can reach up to 20,000 mg/L. The membrane modules can achieve rejection rates for salts and COD as high as 99%+, with a water recovery rate that can reach over 90%, and an overall membrane lifespan of 3-5 years. They are the only reverse osmosis membrane elements that can be disassembled for cleaning and maintenance.

Application areas of DTRO (Disc-Tube Reverse Osmosis) include:

1.Pharmaceuticals (desalination and concentration of antibiotic resin eluates, vitamin concentration)2.Dyes (desalination and concentration, replacing salting-out and acidification)3.Amino acids (decolorization, impurity removal, concentration, desalination)

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com