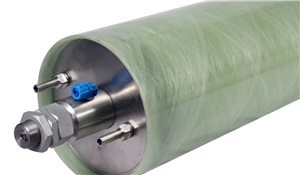

Permeate passes vertically from the outside to the inside of the membrane for separation. The permeate separated by the filtration membrane exits the membrane element through the central pull rod. The separation of concentrate and permeate is achieved through sealing rings between the discs and membrane sheets.

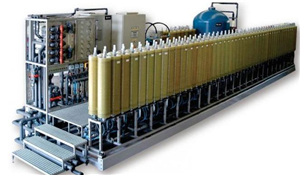

Structurally, DT membrane elements offer the following advantages compared to conventional spiral-wound membranes:

(1) Membrane Replacement and Maintenance

DT membrane elements are extremely easy to maintain: when the fixing nut on the pull rod is loosened, the discs and membrane sheets can be easily removed. The non-destructive opening method of the membrane element allows customers to replace membranes at low cost.

Spiral-wound membranes do not allow for such replacement—if they cannot be cleaned or are damaged, the entire membrane element must be replaced.

(2) Minimal Membrane Scaling and Fouling

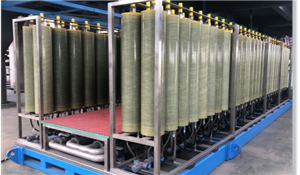

As mentioned previously, DT elements feature an open, wide flow channel and unique disc guides with protrusions, creating turbulent flow within the element. This minimizes scaling, fouling, and concentration polarization on the membrane surface, allowing DT elements to demonstrate excellent performance even at operating pressures up to 120 bar.

(3) Pollution Tolerance

Due to their special structure, they exhibit high resistance to organic pollution. Raw landfill leachate with COD up to 10,000 mg/L can be treated by DTRO membranes after simple suspended solids removal and operate stably, which is incomparable to conventional spiral-wound membranes.

(4) Membrane Cleaning Efficiency and Service Life

DTRO elements feature a 3mm open wide flow channel and unique disc guides with protrusions that create turbulent flow. This significantly reduces scaling, fouling, and concentration polarization on the membrane surface. DTRO elements effectively prevent scaling, reduce membrane fouling, and extend the service life of reverse osmosis membranes. The special structure and hydraulic design of DTRO make the membrane elements easy to clean with excellent flux recovery after cleaning, extending membrane life.

In contrast, traditional spiral-wound membranes only have narrow mesh separators between membrane sheets. Due to the mesh structure, pollutants are trapped inside the membrane element, usually making effective cleaning impossible after some operation. With extended continuous operation, membrane elements eventually require replacement. The service life of spiral-wound elements is typically 2-3 years, and when used for highly polluted wastewater, they need replacement after just 2-3 months.

(5) Low Membrane Replacement Cost

Any single component inside the DTRO element can be replaced individually. The filtration section consists of multiple filter membrane packs and guide discs. When filter membrane packs need replacement, they can be replaced individually, while membranes with good filtration performance can continue to be used, minimizing replacement costs. This is unachievable with spiral-wound, hollow fiber, or other types of membrane elements. For example, when spiral-wound membranes develop patches, local leaks, or require new membranes, the entire membrane element must be replaced.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com