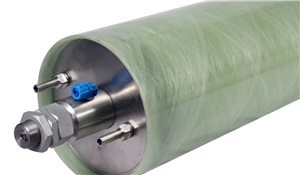

When the membrane module depressurizes and drains, a certain level of vacuum is generated. The lip seal on the end flange opens due to pressure loss, drawing small particulate contaminants around the seal into its edges. When the membrane module is repressurized, these particles remain trapped inside the seal, causing water to leak through the seal ring.

To resolve this issue, follow these steps:

Stop the equipment and depressurize the membrane module. Hold the edge of the pressure vessel and rotate the fiberglass vessel by 45–90°. Restart the system. Minor leakage may persist until operating pressure is reached. Once the system reaches operating pressure, stop and restart it again — after this restart, the leakage will cease.

If the leakage is due to a faulty lip seal, proceed as follows:

Remove the membrane module from the system, then disassemble the pressure vessel. Inspect the contact area between the vessel and the lip seal for scratches or black deposits. If found, smooth or remove them with fine sandpaper. If the vessel is fully disassembled, carefully inspect the other end as well.

Check the lip seal for defects. If any are found, replace it with a new seal. Apply lubricant to the seal, then reinstall the pressure vessel and module.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com