With urban development and the improvement of residents' living standards, the discharge of municipal waste is increasing daily. The generation of large amounts of domestic waste affects our living environment, polluting the air, occupying land, and contaminating water bodies. The disposal of municipal solid waste has become a major challenge for modern cities. Landfill leachate is different from general wastewater; its main characteristics include high BOD5 and COD concentrations, high metal content, significant variations in water quality and quantity, high ammonia nitrogen content, and an imbalance in the ratio of microbial nutrients. Below are the common treatment processes for landfill leachate, which are mainly divided into three major categories:

1. Main content of the Biological Treatment + Membrane Treatment Process:

Leachate flows through the equalization tank into the mesophilic anaerobic tank. After degradation of macromolecular organic pollutants, it enters the anoxic zone of the MBR reactor, mixes with the recirculation water, and enters the aerobic zone of the MBR for aeration to remove TN from the leachate. The effluent from the aerobic tank enters the MBR separator, and the separated sludge concentrate is returned to the anoxic zone of the MBR. The MBR effluent enters the reverse osmosis (RO) system. After treatment by reverse osmosis, the leachate meets the standards for discharge.

2. Main content of the All-Membrane Adsorption Filtration Process:

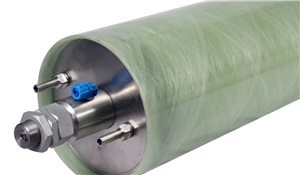

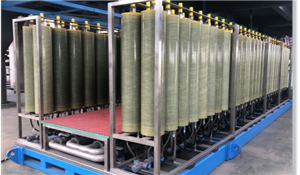

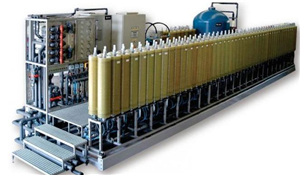

Raw leachate from the landfill site enters from the equalization tank into the high-pressure pump, then enters the first-stage DTRO reverse osmosis membrane filtration via the circulation high-pressure pump. The effluent then enters the second-stage DTRO reverse osmosis system. After two-stage reverse osmosis filtration, the effluent meets the standards for discharge, and the circulation flow is returned to the system for treatment. The first-stage concentrate is recirculated (or returned) to the landfill area for centralized treatment, and the second-stage concentrate is returned to the total inlet. The total water production rate of the system is about 60%.

3. Main content of the Low-Consumption Evaporation + Ion Exchange Treatment Process:

Landfill leachate undergoes online backwash filtration through the equalization tank filter to remove SS and fibers, improving removal efficiency. Then, using the MVC (Mechanical Vapor Compression) evaporation principle, pollutants in the leachate are separated from the water, achieving water purification. Special resin removes ammonia from the distillate to achieve comprehensive compliance of water quality with discharge standards. During the MVC evaporation process, volatile ammonia gas is discharged, and the DI (ion exchange) system absorbs residual acid gases (e.g., HCl) in the leachate.

Currently, the two-stage DTRO reverse osmosis treatment process has gained widespread market recognition due to its simple operation, ability for intermittent operation, high degree of automation, ease of maintenance and management, independence from pretreatment, and good stability, safety, and applicability. The system operates flexibly, starts quickly, is convenient to maintain, has low operating costs, a high degree of automation, and is simple to operate. The effluent quality is good, is not affected by the C/N ratio, total nitrogen and heavy metals can easily meet standards, fully complying with the requirements of the new standards.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com