It is well known that wastewater treatment is a major issue that must be considered for all coal chemical projects, as coal chemical wastewater has a complex composition, containing both solid suspended particles and toxic and harmful substances such as ammonia nitrogen and sulfides. Pollution caused by improper treatment can easily lead to water scarcity due to water quality degradation. Therefore, the issue of wastewater treatment in the coal chemical industry has become a key problem for the industry's development.

Sources of Coal Chemical Wastewater:

The development chain of the coal chemical industry mainly includes coal gasification, coal liquefaction, and coal coking. The generated wastewater specifically includes coking wastewater, coal liquefaction wastewater, and coal gasification wastewater. Coal chemical processes require large amounts of water, primarily for gas washing and condensation, which generates corresponding wastewater. This wastewater contains high concentrations of pollutants and has a complex quality, dominated by phenolic compounds, making it high-concentration industrial wastewater that is difficult to biodegrade.

Classification of Coal Chemical Wastewater:

Coal chemical wastewater is industrial wastewater generated during coal chemical production processes. Its classification varies with the processing technology and mainly includes coal-to-gas wastewater, coal-to-liquid (synthetic fuel) wastewater, coal-to-coke wastewater, and coal-to-methanol/olefins wastewater.

1.Coal-to-Gas Wastewater: Coal gasification wastewater comes from processes such as gas washing, condensation, and purification in gas generators. It is typical wastewater containing aromatic and heterocyclic compounds. It contains numerous types of pollutants, mainly ammonia nitrogen, phenols, petroleum substances, cyanides, sulfides, etc., most of which are toxic and harmful. The treatment difficulty is manifested in: complex wastewater composition, high pollutant concentration requiring high treatment load; toxic substances like phenols and cyanides inhibit microbial activity; poor biodegradability of wastewater, difficulty in biological degradation, etc.

2.Coal-to-Liquid Wastewater: Coal-to-liquid is the process of producing fuels like gasoline, diesel, liquefied gas, and chemicals from solid coal. The wastewater discharged from this process has high COD concentration, chromaticity, emulsification degree, and is difficult to degrade. The main characteristics of high-concentration coal-to-liquid wastewater are: containing sulfur and phenols, relatively low oil and suspended solids concentration, high COD concentration beyond the scope of general biological treatment, and low salt content. This wastewater has large discharge volume, high concentration, and is difficult to treat.

3.Coal-to-Coke Wastewater: Coal-to-coke refers to the process of heating bituminous coal without air to produce coke. The amounts of COD and ammonia nitrogen discharged during coking in China are considerable. The pollutant components in coking wastewater are complex, and pollutant concentrations vary widely. Research shows that coking wastewater contains 15 categories of 558 types of organic substances, mainly high-content phenols and ammonia nitrogen, and low-content but highly toxic organic and inorganic pollutants. It is a typical industrial organic wastewater with large volume, wide distribution, complex composition, toxicity, and difficulty in degradation.

4.Coal-to-Methanol/Olefins Wastewater: The source of coal-to-methanol wastewater is mainly gasification wastewater, characterized by high ammonia nitrogen and COD. Coal-to-olefins wastewater is discharged during the olefin synthesis process after coal-to-methanol production, with high content of harmful substances. Direct discharge causes serious pollution, while treatment methods like biological treatment or direct incineration face high-cost problems.

Characteristics of Coal Chemical Wastewater:

(1) Complex composition, high pollutant concentration: Coal chemical enterprises produce large volumes of wastewater with complex quality, containing a large amount of solid suspended particles, high concentrations, numerous difficult-to-degrade pollutants such as various phenols, cyanides, polycyclic aromatic hydrocarbons, thiocyanates, benzopyrene, quinoline, indole, biphenyl, oil, and other toxic, harmful, and difficult-to-degrade organic pollutants, as well as various inorganic pollutants like ammonia nitrogen and sulfides. The COD and chromaticity of the wastewater are very high, classifying it as difficult-to-treat industrial wastewater.

(2) High hazard, poor biodegradability: Many organic pollutants in coal chemical wastewater are difficult to degrade, making them hazardous. Cyanides are highly toxic substances causing central nervous system poisoning leading to paralysis and asphyxiation; phenols are highly toxic substances with direct toxic effects on various organism cells, causing dizziness and insomnia, and corrosive to mucosal epithelium. High concentrations of ammonia nitrogen in coal chemical wastewater entering water bodies cause odor and easily cause eutrophication, severely damaging the aquatic ecosystem. The high content of some organic substances like heterocyclic and aromatic compounds in coal chemical wastewater, their difficult biological degradability, exceeding the tolerance limits of microorganisms, their toxic effect on microorganisms, unfavorable for their survival, result in poor wastewater biodegradability.

How to Achieve Zero Liquid Discharge (ZLD) for Coal Chemical Wastewater?

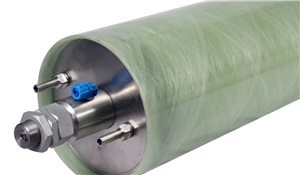

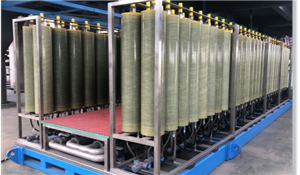

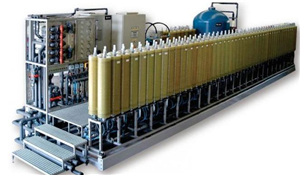

The ultimate goal of ZLD is no discharge, not optimal effluent quality; the effluent indicators only need to meet the water quality requirements for reuse points. Most existing coal chemical wastewater treatment systems choose make-up water for circulating water systems as the main reuse point. According to relevant standards, the limit concentrations for total dissolved solids (TDS) and chemical oxygen demand (COD) in circulating water make-up are 1000 mg/L and 30 mg/L, respectively. The currently selected ZLD processes are mostly multi-stage membrane treatment processes, whose effluent quality is far better than these standard values. Therefore, membrane treatment has become the preferred method for coal chemical wastewater treatment.

Significance of Coal Chemical Wastewater Treatment:

Currently, the new coal chemical industry aims to create clean energy and produce coal-based products such as coal-to-natural gas, coal-to-methanol, coal-to-aromatics, coal-to-ethylene glycol, etc. Its huge advantage of low cost is gradually replacing traditional oil and gas products. However, in China, the distribution of coal resources and water resources is inverse: Shaanxi, Shanxi, Ningxia, etc., possess about 67% of the country's discovered coal resources but less than 4% of its water resources. The serious imbalance in water resource distribution greatly restrict the sustainable and healthy development of the coal chemical industry. While the new coal chemical industry brings great convenience to industrial development, it also faces the severe problem of high water consumption and large wastewater discharge. Statistics show that the wastewater discharge volume for producing 1 ton of olefins and 1 ton of refined oil is approximately 10-15 tons and 4-6 tons, respectively. Direct discharge without treatment will lead to a vicious cycle of water resource scarcity and also cause serious harm to the surrounding environment. Therefore, developing economical and effective treatment processes to reduce the discharge of coal chemical wastewater and enhance its reuse capacity has important practical significance and application value.

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com