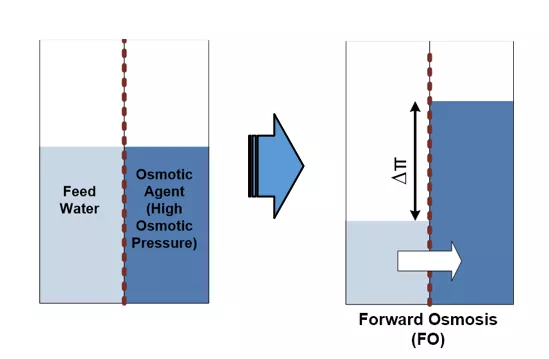

Basic Principles of FO (Forward Osmosis) Technology

Feed water and a saline solution (osmotic agent) — two solutions with different osmotic pressures — are placed on either side of a selectively permeable membrane. Under the osmotic pressure difference, water spontaneously diffuses from the low osmotic pressure side through the semi-permeable membrane to the high osmotic pressure side. This process is the forward osmosis (FO) process. Additionally, FO technology itself offers advantages such as low-pressure or even pressure-less operation, low energy consumption, and high fouling resistance.

Application Fields of the FMBC Process

Third-Generation Leachate Treatment Technology

l FO + AMBC = FMBC Technology, Zero Liquid Discharge (ZLD) Treatment of Concentrate

l FMBC System Recovery Rate >80%, Overall Recovery >97%

l New Construction and Retrofit of Landfill Leachate Treatment Systems

l Emergency Treatment of Accumulated Leachate at Landfills

l Leachate from Waste Incineration Plants

l Concentrating Chemical Production Mother Liquors with FMBC

l Concentrating Food, Beverages, etc. with FMBC Process

l Concentrating Fermented Biogas Slurry from Livestock Wastewater with FMBC Process

l Treating Shale Gas Fracking Flowback Fluid with FMBC Process

FMBC Process Case Studies

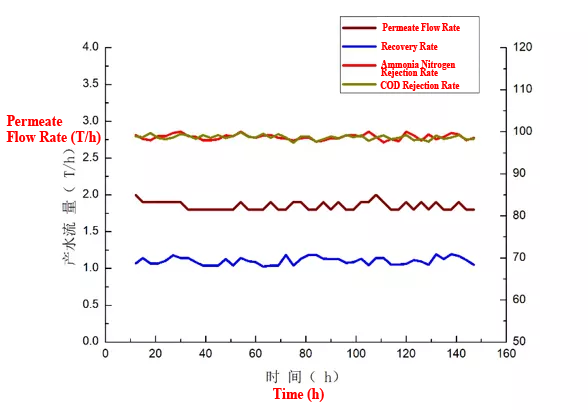

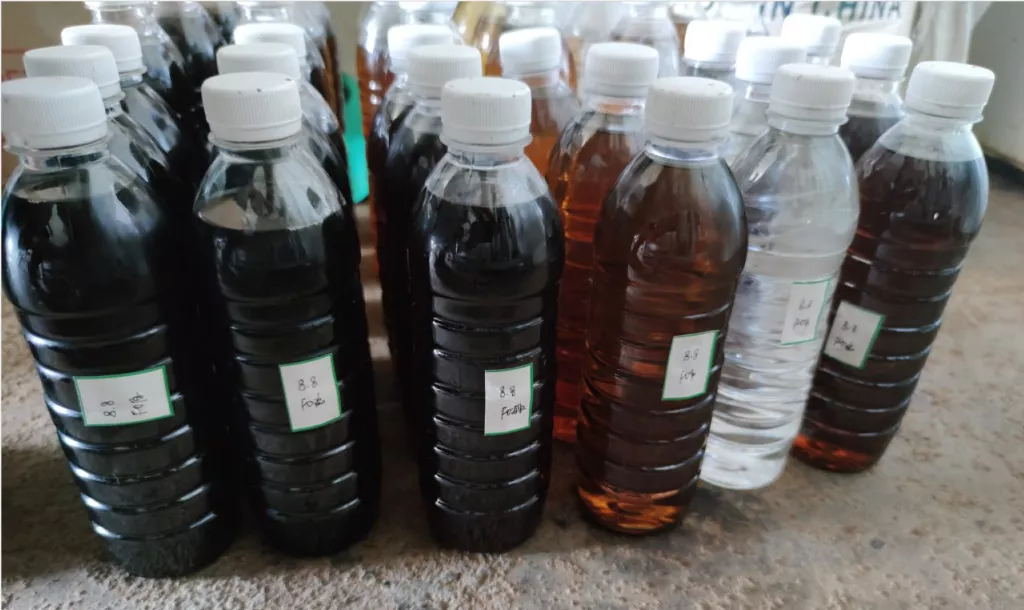

Fenghua, Ningbo Case

Influent: NH3-N 5500 mg/L, COD 6000 mg/L, TDS 20000 mg/L

Effluent: NH3-N <25 mg/L, COD <50 mg/L

System Capacity: 16 t/d, Recovery Rate >70%, 8 h/d

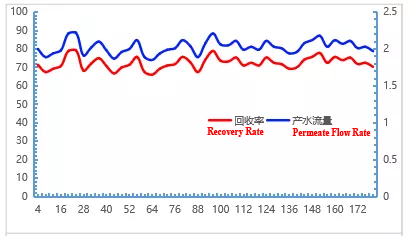

Longgang, Wenzhou Case

Influent: NH3-N 3500 mg/L, COD 10000 mg/L, TDS 15000 mg/L

Effluent: NH3-N <25 mg/L, COD <100 mg/L

System Capacity: 16 t/d, Recovery Rate >80%, 8 h/d

FMBC Process Summary

1.Fouling Resistance: FMBC exhibits strong fouling resistance (against microorganisms, organics, suspended solids, etc.), can operate with chlorine present (up to 10 ppm effective chlorine), has a long cleaning cycle for low-temperature evaporation (up to 60 days), and allows for online cleaning.

2.Operating Costs: FMBC energy consumption is lower than a two-stage DTRO system, chemical consumption is reduced, and low-temperature evaporation operating costs are low.

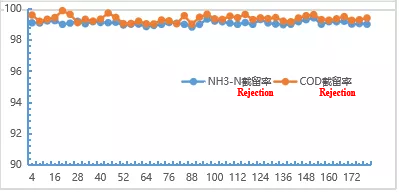

3.Treatment Performance: Compared to DTRO, the FMBC process demonstrates better stability, stable effluent COD and NH3-N levels, and produces better quality distillate from low-temperature evaporation.

4.Equipment Stability: Long cleaning cycles, easy cleaning procedures, high operational availability, and high water production rate (recovery rate) per unit time.

of Desulfurization Wastewater in Power Plants_.jpg)

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com