The main methods for achieving ZLD of concentrated seawater primarily include three approaches: salt pond method (also known as solar evaporation), freezing method, electrodialysis, and AMBC concentration method.

AMBC Technology Introduction

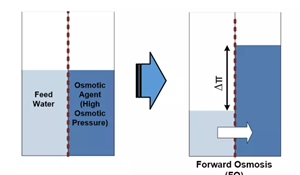

l A membrane concentration system based on the semi-permeability principle and pressure-driven membrane separation technology.

l Ultra-high concentration factor, low energy consumption, conventional high-pressure operation, relatively low investment cost.

l Simple operation, with a process similar to traditional seawater reverse osmosis.

l Breaks through the limitations of traditional reverse osmosis technology, capable of producing brine with concentration up to 21% and higher.

l Power consumption maintained within 9 kWh per ton of feed water (under feed concentration of 7%).

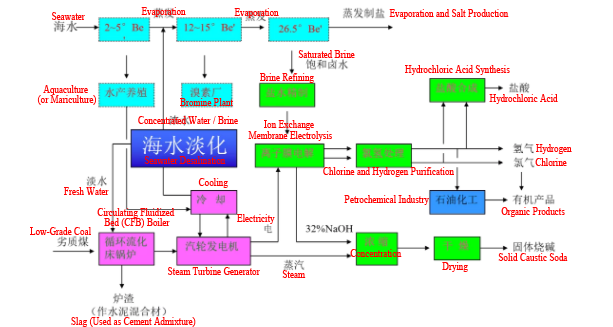

Case Study

Daily Treatment Capacity: 1200 t/d

Treatment Process: MMF + NF + RO + AMBC + MVR

Feed TDS: 35,000 mg/L

Concentrate TDS: >1,400,000 mg/L (>14%)

Final Product Water TDS: <1,000 mg/L

Project Characteristics: Truly achieves "resource utilization" of seawater: produces water suitable for reuse, and concentrated seawater for salt production. Qualified fresh water is produced via nanofiltration and reverse osmosis, while simultaneously using AMBC technology to further concentrate the brine to produce refined salt. This salt has higher purity than solar salt, fully meeting edible standards. Furthermore, due to the high concentration factor, more fresh water can be produced from the brine.

Other Application Areas of AMBC

Application Fields: Thermal power generation, pesticides & fertilizers, pulp & paper, coal chemical industry, pharmaceuticals, metal & non-metal mining, textile printing & dyeing, non-ferrous metal smelting, chemical fibers, oil & gas extraction, chemical raw materials, chemical products, dyeing wastewater.

Process Advantages: Reliable technology utilizing multi-stage special membrane processes; technological innovation that breaks through traditional reverse osmosis limits, concentrate TDS can reach 210,000 mg/L; low operating costs, replaces the traditional concentration stage in ZLD systems, significantly reducing the size of evaporation equipment; simple operation, easy operation and maintenance, highly automated, requires only electricity, eliminating problems and complexities associated with using thermal energy in traditional technologies.

of Desulfurization Wastewater in Power Plants_.jpg)

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com