Currently, the treatment technology and engineering application for leachate from municipal solid waste incineration plants are becoming increasingly mature. The treated effluent can meet the Table 2 standards of the "Standard for Pollution Control on the Landfill Site of Municipal Solid Waste" (GB16889-2008) and the open recirculating cooling water quality standards in Table 1 of "The Reuse of Urban Recycling Water—Water Quality Standard for Industrial Uses" (GB/T19923-2005). The most prevalent process route is "Anaerobic + Biochemical + Membrane Advanced Treatment". However, during actual operation, most leachate treatment projects still face numerous challenges, such as the treatment and disposal of membrane concentrate and non-compliance of total nitrogen. Furthermore, issues like high operating costs and secondary pollution also hinder the sustainable development of municipal solid waste treatment. Overall, the current leachate treatment process faces several urgent problems requiring resolution.

I. Existing Challenges in Leachate Treatment

1. Membrane Concentrate Issue

Significant membrane concentrate is generated during membrane advanced treatment. This concentrate is high-salinity wastewater, difficult to treat via conventional biochemical or simple separation methods. As environmental regulations become stricter, the options for reusing membrane concentrate from leachate treatment facilities at waste incineration plants back to the main plant are limited. Therefore, it is necessary to further increase the system water recovery rate, reduce membrane concentrate production, and properly handle the generated concentrate. Especially for large-scale leachate projects, the membrane concentrate volume, nearly 30% of the total leachate, cannot be fully consumed. Although back-spraying concentrate can address reuse, it affects the plant's power generation, reducing economic benefits.

During environmental impact assessments for some renovation, expansion, and new projects, experts have questioned the reuse of membrane concentrate for lime slurry preparation and fly ash stabilization. Some projects even prohibit its use for lime slurry. Additionally, these projects face challenges in reusing other high-salinity streams like flue gas wash water, bleaching wastewater, and cooling tower blowdown. This not only complicates full-plant concentrate reuse but also causes secondary pollution. The membrane concentrate issue is directly related to the goal of complete leachate treatment and "zero liquid discharge" at incineration plants, necessitating practical measures for effective treatment and disposal.

2. Total Nitrogen Issue

Current common nitrogen removal technologies for leachate include biological nitrogen removal, ammonia stripping, and membrane methods. While these achieve good results facilitating compliance, they have drawbacks. For example, biological nitrification can make ammonia nitrogen compliant, but denitrification often fails to meet total nitrogen standards; it's also complex, unstable, requires large area, and creates poor working conditions. Ammonia stripping removes most ammonia nitrogen but requires additional biochemical treatment for compliance, adds alkalinity risking scaling, and risks ammonia escape causing secondary pollution. Membrane-based nitrogen removal uses gas membranes: alkalinity converts ammonium ions to free ammonia, which permeates the membrane and is absorbed by acid on the permeate side forming ammonium salts. This method demands high feed quality (removal of SS, scaling compounds), requires alkalinity addition and heating, consumes acid for absorption, and poses ammonium salt disposal issues, leading to poor economics. Thus, high ammonia nitrogen concentrations not only surge costs but also impact treatment effectiveness, making finding efficient high-ammonia removal methods urgent.

3. Odor and Noise Issues

Most leachate treatment stations are in remote areas with poor environmental conditions, so odor pollution is often overlooked. Many lack odor control facilities, significantly impacting surroundings. Odor control facilities should be built concurrently with treatment facilities and meet emission standards. Noise impact is also often neglected; some plants lack mitigation measures, leading to exceedances. Reasonable measures are needed to address noise pollution.

4. Excess Sludge Issue

High pollutant concentration in leachate and the common use of aerobic biochemical processes result in substantial excess sludge production, with dewatered sludge moisture content exceeding 75%. Typically incinerated, this consumes significant heat, reducing power generation efficiency, and generates bottom ash affecting combustion. Effective processes and technologies are urgently needed to fundamentally address the high sludge production rate.

5. Energy Consumption Issue

Energy consumption for leachate treatment in China is generally high, due to process selection and equipment advancement. Thus, significant potential exists for energy saving and emission reduction. Reducing energy consumption is a crucial long-term task, requiring efforts in engineering design, equipment selection, operation, and maintenance to lower costs and improve economic efficiency.

II. Future Development Trends in Leachate Treatment

1. Development of New Technologies

Leachate treatment involves many technologies and equipment, but system complexity has exposed problems, necessitating new solutions. For instance, using liquid oxygen instead of air aeration in MBR can improve aerobic efficiency and operating conditions. For NF/RO, using chemical softening + microfiltration instead of NF, and DTRO instead of RO, can effectively increase recovery.

For membrane concentrate, emerging technologies like wet oxidation, full membrane processes, electrochemical methods, and evaporation (especially mechanical vapor recompression MVR/MVC and submerged combustion evaporation) offer promise for concentrate volume reduction. However, evaporation requires specific feed quality regarding ammonia, VOCs, and dissolved recalcitrant organics, and high hardness causes scaling, so technical improvements are still needed.

2. Development of New Processes

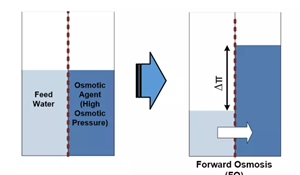

Developing new processes characterized by stable operation, high effluent quality, low concentrate production, good operating environment, low cost, and high resource recovery is the key trend. Processes have evolved from "Coagulation + Ammonia Stripping + UBF + SBR + MBR" to "Pretreatment + MBR + NF/Softening + RO/DTRO/STRO", steadily raising discharge standards, achieving ~70% water recovery, and improving concentrate quality. The latest generation process like "Pretreatment + FO + AMBC/HPRO" uses Forward Osmosis (higher fouling resistance, extending cleaning cycles) followed by high-concentration factor technology (AMBC) for stable final effluent. These advancements significantly improve system availability, compliance rate, and recovery (>85%).

III. Summary

Adopting new technologies significantly reduces footprint and energy consumption, with effluent quality surpassing traditional processes and cooling water reuse standards. Thus, developing new leachate treatment processes not only helps solve urgent industry problems like poor effluent quality and high concentrate production but also promotes the sustainable development of the leachate treatment industry.

of Desulfurization Wastewater in Power Plants_.jpg)

Henan Yuanhede Industrial Technology Co., Ltd.

East Industrial Park, Yuzhou City, Henan Province, China.

(+86)139 3822 7726

info@yhdegroup.com

www.yhdegroup.com